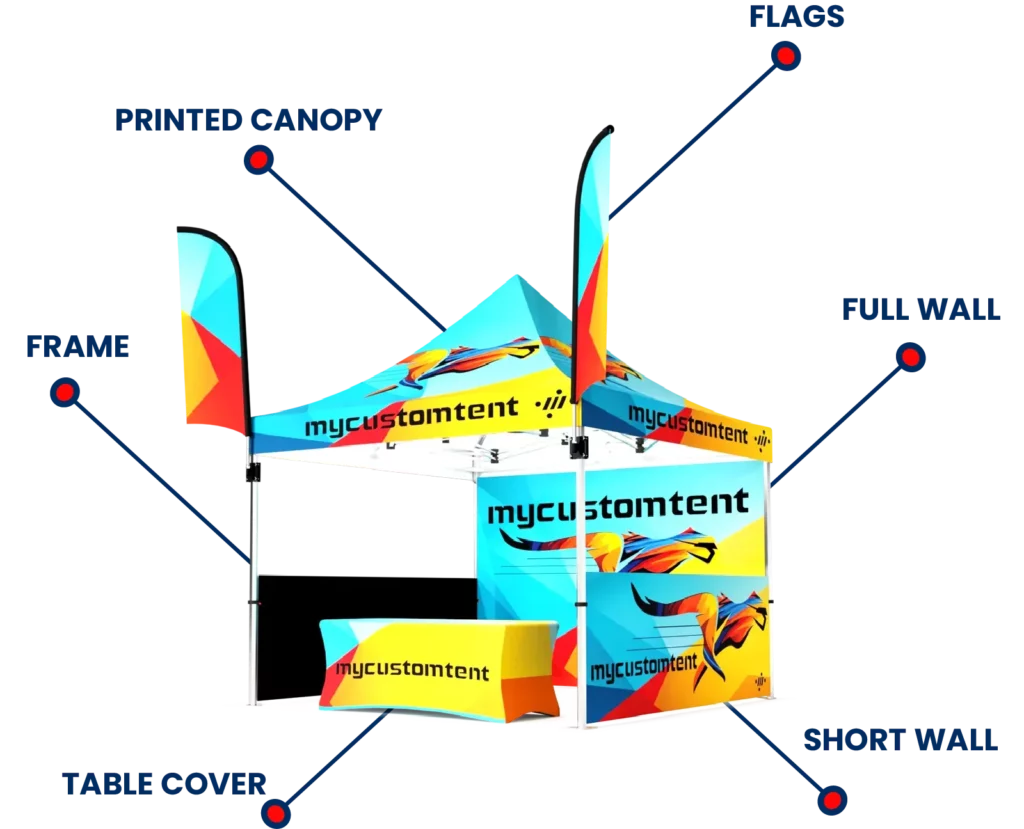

HOW CUSTOM POP-UP TENT CANOPIES ARE MADE

Explore our craftsmanship, materials, and expertise that make our tents the best choice for your brand!

Learn more about how our engineering team makes great things!

Explore our process beginning with our professional design service, durable frame construction, vibrant printing process, high quality fabrics, quality assurance priority and fast delivery process.

Durable Frame Construction

Our tent frames are engineered from lightweight yet sturdy aluminum, ensuring long-lasting durability and easy setup.

- Commercial grade (meant for use every weekend).

- BEEFY 40mm hex shape legs

- Premium grade aluminum (light + strong)

- 10×10, 10×15 and 10×20 sizes available

- Lifetime warranty (see policy page)

Printing Process

Our printing process ensures your custom pop-up tent canopy stands out with unmatched vibrancy and durability. Using advanced dye sublimation technology, we embed the brightest and most vibrant inks directly into the fabric. This scientific process creates a permanent bond, making the designs an integral part of the material—no peeling, cracking, or fading over time.

Our canopies are built to perform in any environment, offering more than just eye-catching visuals. Here’s what makes our printing process exceptional.

- Bright and Vibrant Ink: We use the best ink on the market that is specifically developed for outdoor applications.

- Weather resistant: Our fabric and ink is built to withstand UV, Water and Fire.

- 600 D Thick Fabric: We don’t use a thinner 500D fabric like most of our competition.

- Dye Sublimation Printing: This scientific process creates a permanent bond of the ink and the fabric to eliminate any peeling or cracking issues.